The Bexley Open Air Pool was built in Danson Park in 1936. The estate was privately owned by Sir John Boyd, a wealth merchant. The mansion is Grade II listed and is now owned by the london Borough of Bexley.

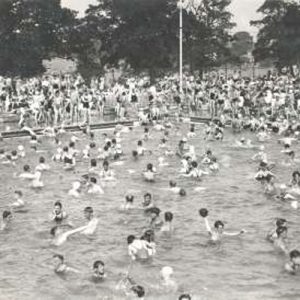

The pool was well used with a restaurant and picnic area and two smaller pools for children.

The plans for the pool were reported in January 1935 in Baths and Bath Engineering, who said

‘The Ministry of Health has approved in principle the construction of a swimming pool in Danson Park by the urban district council, at the approximate cost of £30,000.‘

They later reported, in September 1935,

‘An open-air reinforced concrete swimming bath 220′ x 90′ and two paddling pools, each 45′ x 30′ are to be construction in Danson Park, Welling, Kent, for the urban district council.‘

By the time the pool was built it had shrunk by 55 metres, presumably for cost reasons although the site is still very large.

The lido was famous for having a mangle which could squeeze excess water from towels enabling the processing of 1,200 per day.

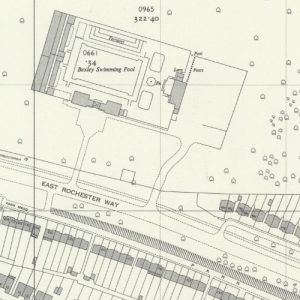

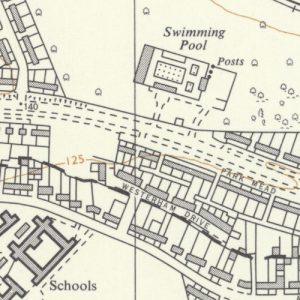

| Name | Bexley Open Air Pool Danson Park, East Rochester Way, Bexley, DA15 0PW |

| Coordinates | 51°27’05.3″N 0°06’54.0″E |

| Built / opened | 25th July 1936 |

| Cost | £26,250 |

| Dimensions | 165′ x 90′ |

| Capacity | 600,000 gallons across three pools |

| Water type | Filtered fresh wster. Chloramine process |

| Depth(s) | 3′ to 10′ |

| Diving | Fixed boards 1m, 3m, and 5m Springboards 2 x 1m, 3m |

| Changing facilities | 144 cubicles, each with 6 steel lockers – 864 bathers at any time |

| Second pool | Two paddling pools 45′ x 30′, 1′ to 2′ deep 45′ x 30′, 2′ to 3′ deep |

| Spectator seating | Cafe, paved terraces. |

| Designer | G A Joy |

| Date closed | 1979 |

| Status | Demolished 1982 |

| On site now | Grass |

| Last updated | 10th December 2025 |

URBAN DISTRICT COUNCIL OF BEXLEY

Appointment of Open-Air Bath Superintendent

The Council invites applications from duly qualified persons for the above-mentioned post at a salary of £300 per annum.

Applicants must hold a recognised Life Saving Certificate and must have had previous experience in Filtration, Heating, Chlorination Plant and general swimming pool administration.

Preference will be given to candidates having in addition to the above qualifications, experience in catering Management.

Applications in candidates’ own handwriting, endorsed “Bath Superintendent” accompanied by copies of three recent testimonials must be delivered to the undermentioned not later than noon on the 20th June 1936.

Canvassing, either directly or indirectly will be a disqualification.

W Woodward

Clerk to the Council

Council Offices, Bexleyheath

June 1936

Baths and Bath Engineering, October 1936

Bexley Open Air Swimming Pool

Urban District Council Scheme in Danson Park, Welling

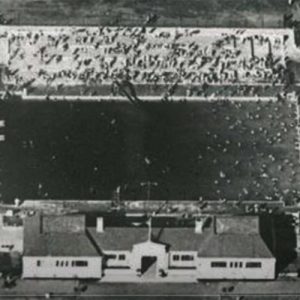

Danson Park, situated almost in the centre of the urban district of Bexley, now possesses amongst other sport amenities a fine open-air swimming pool, which was opened by the chairman of the council (Coun. A. G. Williams. J.P.) in July last.

Conception of the Scheme

The idea that Bexley should have its own swimming pool was first conceived as far back as 1933, and the idea took concrete form when at n meeting of the council in October 1934, it was resolved that a scheme should be prepared and application made to the Minister of Health for sanction to raise the necessary loan. Following this resolution the preparation of the scheme was put in hand, and as the council felt that Bexley was worthy of a pool that would have popular appeal over n large area, a somewhat ambitious scheme was formulated. This scheme comprised swimming pool 220 ft. by 90 ft., with two children’s paddling pools, cafe, administrative building, conveniences. showers, shelters, reinforced concrete sun-bathing terraces, dressing accommodation on a liberal scale, lawns, flower beds, and paved areas.

The scheme, having been approved by the council, was, together with an estimate of cost, submitted to the Ministry of Health. Various consultations took place between officials of the Ministry and of the council, and eventually a public inquiry was held. Certain opposition to the scheme was evident at the inquiry (mainly from those who favoured a covered indoor bath), but after further careful consideration and additional consultations at the Ministry, the final sanction to the preliminary scheme and estimate was obtained. The next stage in the acquisition of the pool was less fortunate. Tenders from building contractors were invited by public advertisement, and after these were received and opened, it was found that the lowest tender was in excess of the council’s expectations. Endeavours were made to reduce the cost of the scheme, but without success, and acting on the advice of the Ministry, the council were forced to abandon several features of the scheme as originally planned. Following this setback an amended scheme was prepared in which modifications were made and the pool and its amenities reduced in size, with the result that the scheme as now executed was decided upon. Tenders for this amended scheme were obtained, and the lowest tender comparing favourably with the amended estimate, the sanction of the Ministry was granted and work commenced in February 1936.

The Swimming and Children’s Pools

The scheme includes three pools. The main swimming pool, which is 165 ft. by 90 ft., with total depth of 10 ft. at the deep end, gradually diminishing to 3 ft. at the shallow end. The diving stage incorporates one high diving board at 5 m. level, one firm board at 3 m. level, one springboard at 3 m. level, and one firm board at 1 m. level. In addition, there are two separate springboards at 1 m. level, and two chutes that discharge obliquely into the 6 ft. depth of water. This pool is constructed with reinforced concrete walls andbottom; the walls being covered on the inside with apolished blue terrazzo and the bottom with white cement. The other two pools are provided for the use of children, and are each 45 ft. by 30 ft., with depths that vary in the case of one from 1ft. to 2 ft. and in the case of the other from 2 ft. to 3 ft. These pools are constructed in concrete and are covered on the inside with white cement.

Water Purification, Heating and Laundry Plant

The three pools contain approximately 600,000 gal of water, and this water is maintained in a state of purity throughout the season by means of an up-to-date purification plant. The plant, which is situated in the administrative building, has a capacity of 100,000 gal. per hour, a filtration area of 384 sq. ft., and a filtration rate of 250 gal. per sq. ft. per hour. The water is drawn from the deep end of the pool through two polished gunmetal outlet gratings through a 14 in. bore suction main. A strainer is fitted in this pipe to arrest large particles of dirt such as leaves, fluff from bathing costumes, etc., which are liable to choke the pump. Centrifugal type circulating pumps are supplied in duplicate and each is driven by a 30 h.p. electric motor. The water is treated with the coagulating chemicals alumina and soda by means of a shunt fed type of apparatus. This is operated by the differential head set up across the venturi tube fitted in the pump delivery. Water from the high-pressure side of the venturi is passed through a measuring device and a vessel containing the chemical. Here it is transformed into a saturated solution and returned in this for to the throat of the venturi. The latter also operates a flow indicator which shows the quantity of water being pumped. This method of chemical dosage employing a venturi tube ensures that any variation in the flow of water produces a proportional variation in the flow of chemical solution This maintains a constant chemical dose. The treated water is then pumped through the filters where all dirt particles are removed. As the dirt accumulates on the sand bed the resistance to the passage of the water increases and is shown on the pressure gauges provided. After a period of operation, the filters require washing. This process is carried out by first of all blowing compressed air into the base of the filter by means of a motor driven rotary air compressor. The air passes upwards through the sand bed and in its passage displaces the sand grains and produces a violent scouring action which loosens the collected dirt. After a short period of this air scour the compressor is shut down and n reverse flow of water is pumped through the filters carrying the loosened dirt away to waste. After filtration, the water is aerated in an enclosed type of aerator. The air is provided by means of a venturi air induction tube which is designed to produce a pressure at the throat below that of atmosphere. Air is therefore drawn in at this point and is fed into the base of a contact chamber where thorough mixing takes places The excess air and foul gases are released through a vent pipe fitted with an automatic valve. Sterilisation is effected by the chloramine process. A small dose of ammonia is first added to the water and is followed by chlorine, the two forming the compound chloramine.

In addition to filtration chlorination and aeration, the water is heated. After leaving the filters and chlorinator, the water is conveyed by means of pipes to two gas fired boilers through which it is circulated every six hours. By these means it is possible to maintain an equable temperature in the water regardless of the climatic variations.

The purified, sterilised and heated water is finally delivered to the shallow end of the pool through five inlets. If required approximately 25 per cent. of the total flow can be by-passed over the cascade aerator.

The two paddling pools are fed from the cascade basin thorough automatic float-controlled valves. The water level in these pools is maintained 18 in. above bath water level.

The level of the water in the footbaths is 6 in. above bath water level, and the water is maintained at the correct height by means of standpipe outlets. The water feeding the footbaths is taken from the filtered water main after sterilisation. Situated in the heating chamber are also a steam boiler and calorifier. These provide constant hot water to the lavatory basins in the conveniences and to the showers and foot sprays. Adjoining the heating chamber is the laundry. The laundry includes a washing machine, hydroextractor, wringers and steam-heated drying room, and is capable of dealing with 1,200 towels per day.

General

The administrative building also contains accommodation for the superintendent’s office, ticket office, and main entrance with turnstiles, and is a brick-built building with green tiled roof. The walls of the building are covered on the outside with white cement.

Facing the shallow end of the pool is the café building which includes the cafe with paved terrace, buffet, kitchen, and conveniences. This building is also built of brick faced with white cement on the outside and roofed with green tiles. ‘The interior of the cafe is provided with a plaster ceiling and walls above an Australian walnut dado finished with an oak floor. The whole building is surmounted by a turret on the roof which in addition to providing ventilation to the cafe, accommodates an electric synchronised clock and one of the loudspeakers that form part of the public address equipment. The cascade aerator, which is provided with floodlighting. is situated in front of the cafe.

At the deep end of the pool are a group of smaller buildings, viz., conveniences for the bathers and a building containing hot showers and foot sprays flanked by the dressing boxes, which are 144 in number equally divided between both sexes. Each dressing cubicle is equipped with six steel lockers, thereby providing dressing accommodation for 864 bathers at any one period.

The pool is surrounded by large, paved areas and grass terraces. The grass terraces are provided adjoining the cafe for the use of spectators, while terraces formed of artificial stone paving slabs laid chequer pattern in buff and grey tones are provided for sunbathing. A low rail of anodised aluminium is provided around the main pool to guide bathers into the footbaths before entering the water. There are eight footbaths.

Floodlights on standards 30 ft. high are placed around the main pool. In addition, the whole of the buildings and surrounds are equipped with ordinary lighting units.

Behind the cafe building is a spacious car park providing accommodation for approximately 250 cars.

Loudspeakers are fixed in convenient positions around the pool and in the turret of the cafe from which it will be possible to relay announcements and music from a microphone in the superintendent’s office and for the convenience of the café patrons, a separate loudspeaker is provided in the cafe.

Coun. E., W. Higgs is the chairman of the bathscommittee and Mr. W. Woodward, clerk, and solicitor to the council. Mr. C. B. Scothern, M.N.A.B.S., lately hath superintendent, Southall-Norwood open air swimming pool, has been appointed as superintendent of the Bexley swimming pool.

Engineer and Contractors

The whole of the scheme has been executed under the direction and supervision of the council’s surveyor (Mr. G. A. Joy, F.S.I.) by the contractors, S. H. Alabaster, Ltd., of Bexleyheath, and the following specialist firms have contributed to the preparation and execution of the scheme.

- Messrs, Young and Brown, F.F.S.I., quantity surveyors.

- The Indented Bar and Concrete Engineering Co. reinforced concrete engineers.

- The Candy Filter Co., Ltd., water purification plant.

- Donald Smith and Co., heating installation, laundry plant, and equipment.

- Spencer, Heath and George, Ltd., diving stages, etc.

- The General Electric Co., Ltd., public address equipment.

- Messrs. Cooke, Troughton and Simms, Ltd., clothes lockers.

- The Leeds Fireclay Co., sanitary fittings.

- Atlas Stone Co., Ltd., artificial stone, and cascade aerator.

- The Standard Pavements Co., and The Standard Paving Co., scum trough, edging and lining to main pool.

- George Edwards, of Dartford, wrought iron gates:

- The Marley Tile Co., roof tiling.

- The Aston Construction Co. steelwork.

- The Crittall Manufacturing Co., Ltd., metal windows, and doors.

![]()