Stanley Park is in Anfield and is one of Liverpool’s great parks built in the Victorian era. It opened in 1870 and was designed by Edward Kemp. It is Grade II* listed. It had a number of recreational facilities including bowling greens and an open-air theatre.

The open-air pool seems to be lesser known. It was proposed in 1922 and was built by Walter Spencer of Aintree, opening in 1923. It was situated in the Northeast corner of what is now the boating lake. It was 75 feet by 35 feet and was heated. There was a paddling pool and a larger cold-water pond set aside for swimming. The facility cost £6,515 to build.

The pool was emptied during WWII and when it was re-filled it was found to have developed significant cracks. Extensive remedials works were carried out in 1948 that took just over 5 weeks to complete and cost £961.

The site seems to have been part of a fishing pond originally. When the pool closed the northern edge of the paddling pool was incorporated into the bank of the boating lake and the rest of the site was absorbed back into the lake from whence it came.

| Name | Stanley Park Swimming Bath Priory Road, Anfield, Liverpol, Merseyside, L4 0TQ, England |

| Coordinates | 53°26’13.6″N 2°57’51.4″W |

| Built / opened | 25th July 1923 |

| Cost | £6,515 |

| Dimensions | 75′ x 35′ |

| Capacity | 125,000 gallons |

| Water type | Freshwater |

| Depth(s) | 3′ to ‘ 6″ |

| Diving | Four-level timber fixed diving platform max approx. 1m |

| Changing facilities | |

| Second pool | Paddling pool (6″ to 6′) and large cold water pond. |

| Spectator seating | |

| Designer | |

| Date closed | August 1963 |

| Status | Demolished |

| On site now | Absorbed into lake |

| Last updated | 30th August 2025 |

Liverpool Weekly Courier Saturday 13 May 1922

OPEN-AIR SWIMMING BATHS

The scheme for the provision of an open-air swimming bath in Stanley Park is advanced a stage, the matter being again before the Baths Committee. As previously stated, plans for the new bath have already been approved, and when certain matters of detail connected with the scheme have been completed, the work will be commenced, and it is hoped to have it finished later in the season. The construction will provide work for a considerable number of the unemployed.

Liverpool Echo Wednesday 25 July 1923

OPEN SESAME OF HEALTH AND PLEASURE

STANLEY PARK OPEN AIR BATHS OPENED TO-DAY

The members of the Parks and Gardens Committee and the Baths Committee attended Stanley Park, this afternoon, on the occasion of the opening of the open- air baths and paddling pond. Swimming demonstrations were given by Miss May Spencer – who won the English backstroke championship last Saturday at Yarmouth, Miss Vera Tanner, and Miss Freda Turner, after which the public were admitted to the baths. In a very few minutes there were a large number of swimmers of both sexes in the water, and the paddling pond was quickly thronged with children. The Lord Mayor was unable to be present owing to the Royal visit.

Liverpool Evening Express Thursday 15 February 1923

Liverpool’s Open-Air Baths

Work has already began on the new open-air Baths in Stanley Park, which it is hoped will completed by May 31st. The scheme which was exclusively detailed in the Express a few months ago provides for a large opon-air swimming bath (B) of which the water will be heated and very extensive swimming paddling pond (C) which will vary in depth from 6 inches to 6 feet. “A” in the plan represents the lake and it will noticed the scheme will not deprive boaters of much space. The shaded square shows where dressing station accommodation for both sexes will be built. A bridge, at present, stands over the spot. The scheme is to cost about £6,500, 60 per cent of which will be borne by the Government, on the understanding that unemployed men are given the work through the Board of Guardians and the Labour Exchanges.

Baths Bulletin June 1948

GUNITE AND CEMENTATION REPAIRS TO AN OPEN-AIR SWIMMING BATH AT LIVERPOOL

Repair work of an interesting nature has recently been carried out to the warm water swimming bath at Stanley Park, Liverpool, for the Baths and Washhouses Department of the Liverpool Corporation.

The Stanley Park baths comprise a large cold-water pond, a paddling pool, and a small warm water plunge bath. The latter measures 75′ x 35′ and is 3′ deep at the shallow end and 6′ 6″ at the deep end and was constructed in 1923. The walls and floor are of reinforced concrete 9″ thick. A 14″ brick wall was built along the S.E. side, at a later date, and spaced 12″ from the main reinforced concrete wall to form a scum channel. A series of openings were left in the brick wall at normal full water level so that this wall serves as a weir over which water and scum are carried to be drained off through a pipe in the aforementioned scum channel, whence it is led back to the filtration and heating plants. The filtered and heated water is admitted to the bath by four 4″ pipes set in the N.W. wall.

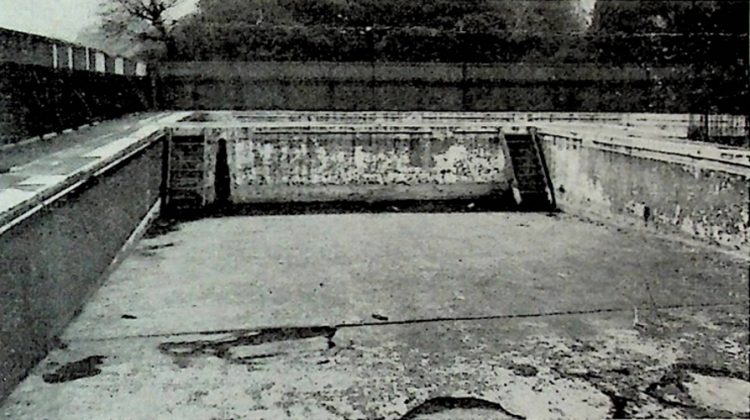

The accompanying photograph gives a general view of the bath before repair, and the longitudinal and cross sections give further details and indicate the method of repair.

The bath was out of use and empty during the war years and when brought back into commission during the summer of 1946 there was a considerable loss of water, amounting to approximately 18″ drop in water level in 24 hours, equivalent to 22,000 gallons of water lost daily. This loss was a particularly serious matter as the water is heated by electricity—an expensive method of heating. Another disturbing element was the possibility that the water going to waste was flushing out the fine material from the foundations and thus endangering the stability of the structure.

An attempt had been made to reduce the leakage by hand rendering over cracks in the floor and walls, but this proved ineffective, and it became obvious that a complete investigation as to the cause of the leakage and a scientific repair based on observations obtained during the investigation were essential.

Messrs. Whitley Moran & Co. Ltd., Gunite and Cementation specialists, of Liverpool, were invited to make an examination of the bath and draw up proposals for the repair work.

It was evident that the N.W. wall of the bath had settled slightly causing four vertical cracks in this wall, two of which extended right across the floor. There were also two vertical cracks in the opposite wall, i.e., adjacent to the scum channel, also probably caused by slight settlement. There were a number of cracks in the floor, some of which might be attributed to original construction joints, and others due to movement of the bath. A 3″ thick rendering on the floor had broken away in many places, exposing the concrete beneath, and there were numerous hollow sounding spots which indicated that the greater part of the rendering had lost its bond and was loose. There were indications that there were some voids beneath the floor slab.

The recommendations made as a result of these findings were that a number of holes be drilled in the floor and injection pipes set in. The holes would be arranged along the lines of the major cracks and elsewhere in such numbers and positions as to ensure that liquid cement grout injected under pressure through the pipes would penetrate to all parts requiring consolidation. The S.E. wall, i.e., the wall behind the weir wall, would be similarly treated by drilling holes at suitable intervals through the cracks and at other possible points of leakage. The existing rendering, where loose or defective, would be cut away. The cracks in the walls and floors would be chased out in the form of a “V” to a depth of approximately 1 in. and plugged with mastic bitumen. The walls and floor would then be thoroughly cleaned by wire brushing and hacked to provide a key. A 3″ x 6″ x 8g welded steel reinforcing fabric would be fixed to the walls and floor and 1 ½ in. thickness of Gunite applied over all. A special type of expansion joint would be formed in the Gunite along the line of the major crack or construction joint in the floor (this crack can be clearly seen in the foreground of the photograph).

Owing to the very restricted space in the scum channel, it was not possible to carry the reinforced Gunite behind the brick weir wall, which would have been the ideal solution, and it was therefore necessary to provide for very thorough pressure grouting of the floor of this channel. The Gunite on the other walls was finished off at a few inches above top water level by turning into a horizontal chase cut in the concrete.

These proposals were accepted in their entirety by the Baths Committee, and Messrs. Whitley Moran & Co., Ltd., were instructed to proceed with the repairs as outlined.

When work commenced on the stripping of the existing rendering where it sounded hollow, it was found that the action of cutting away these areas loosened the rendering over considerably larger areas. It became clear that the hand rendering over the greater part of the floor of the bath had, in fact, very little bond and ultimately almost the entire floor had to be stripped of this rendering.

The crack across the floor shown in photograph No. 1 and referred to above, continued up the N.W. wall and. as previously mentioned, it was decided to form a special type of expansion joint in the Gunite along the line of this crack. The crack was opened out and plugged with mastic bitumen as in the case of the other cracks. Strips of roofing felt 1 ¼ in. deep were fixed on edge by lightly tacking them to a board laid along the line of the joint. Large-head galvanised wire nails were left projecting horizontally from the roofing felt. The 1 ½ in. Gunite was carried up to the board on one side thus covering the roofing felt and gripping the projecting galvanised nails. When the Gunite had set thoroughly the board was carefully withdrawn and the roofing felt remained in position, being held by the galvanised nails embedded in the Gunite. The Gunite was then carried up to the other side of the joint.

At this stage there was a thickness of ¼ in. Gunite over the top edge of the roofing felt and this was cut away and the joint sealed off with a special mastic which remains permanently plastic. The roofing felt being built up in four thicknesses and being itself compressible ensured that an adequate amount of movement of the joint would be possible. The 3″ x 6″ x 8g. steel fabric reinforcement was kept back 1 in. on either side of the joint so as to ensure that any movement which took place would be along the line of the prepared joint.

Since the work was carried out in the winter the joint was designed to provide for expansion of the concrete and consequently for a tendency for the joint to close. Had the work been carried out in the hot weather the form of joint to be provided would have been different as it would have been necessary to allow for contraction of the concrete and consequent opening of the joint. Special methods were adopted for dealing with irregularities or “wandering” of the line of the crack.

The Gunite was given a wood-float finish throughout. The Gunite pre-mix consisted of one part of Portland cement and three parts of washed sharp sand, graded from about 3/16″ down to fines which was projected into position under pressure by means of a cement gun. The force of application is considerable; the individual grains of sand being tamped home by their own velocity. This results in a material of high density and durability with properties superior to those of concrete or mortar. An important feature of the process is the reduction in water content; no excess water being needed to secure workability; this further enhances the density of Gunite and reduces the liability of crazing to a minimum. No special admixtures are used, the extreme density of the Gunite obtained by this method of application makes any admixtures entirely unnecessary.

Had it been possible to carry the Gunite behind the weir wall and up to the S.E. wall, less attention to pressure grouting in the floor and outer wall at the scum channel would have been required and there would have been no doubt as to the proposed repairs being 100% effective since the Gunite would form a complete lining and. in effect. produce a water-tight tank in the bath. Cementation would then have merely been required for filling voids which had been washed out under the floor.

In actual fact the repairs, despite the difficulties encountered, have proved entirely satisfactory. The Baths Department carried out certain repairs to the inlet pipes and thereafter the bath was put under test. When the bath was filled there was a slight drop of water over the first three weeks as had been anticipated, the fall amounting to approximately 3/16″. This was accounted for by the fact that the Gunite takes up some water for a period of several weeks after it is applied. No further fall in water level was detected after this initial period, and it is accordingly believed that the trouble has been completely cured for all time. The total cost was £961, and the repairs were completed in 5 ½ weeks.

![]()