Congleton saw the opening of their new outdoor swimming and paddling pools in May 1936. The pool was a modest 105’ x 45’ but the paddling pool was a whopping 90ft in diameter.

The pool was situated near Congleton Park, separated from the main area by the course of the River Dane. It had administrative buildings with French doors overlooking the pool and spectators terrace that could accommodate 200.

The pool was opened by the Mayoress, Mrs F C Pass who participated in a ceremonial handing over of a silver key from the contractors, Messrs. Bolton and Hayes where she then unlocked to pool.

By 1969, the pool needed a fund-raising committee to generate money for improvements, one of which was to put a roof over the pool. The committee were rather too successful, and the result was that Congleton Borough Council decided to build a new state of the art indoor pool. The funds were spent on providing equipment for the new pool and the committee was disbanded in 1979.

The pool probably closed in 1980, but we cannot find an exact date. In 1980, work started on the pool site to construct the Daneside Theatre,

Both the theatre and paddling pool remain in 2025.

| Name | Congleton Open Air Swimming Bath Park Road, Congleton, Cheshire, CW12 1DP, England |

| Coordinates | 53°09’56.7″N 2°12’38.6″W |

| Built / opened | 23rd May 1936 by Mrs F C Pass, Mayoress |

| Cost | £6,000 |

| Dimensions | 105′ x 45′ |

| Capacity | 180,000 gallons |

| Water type | Fresh water |

| Depth(s) | 3′ to 7′ |

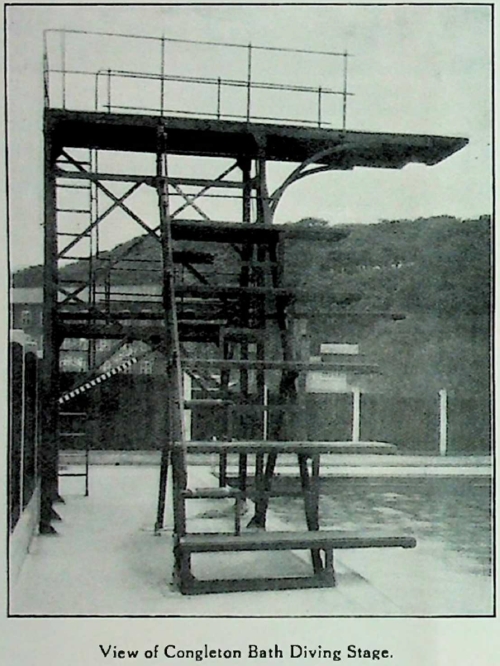

| Diving | 3m springboad, 5m fixed board |

| Changing facilities | Cubicles, showers and foot baths |

| Second pool | Adjacent large paddling pool (90′ diam) that remains in 2025 |

| Spectator seating | For 200 spectators |

| Designer | Mr J Hood, borough surveyor in collaboration with Messrs. L. G. Mouchel and Partners, Ltd., civil engineers, London. |

| Date closed | Approx. 1980 when Daneside Theatre works commenced |

| Status | Demolished |

| On site now | Daneside Theatre |

| Last updated | 9th December 2025 |

Baths and Bath Engineering, September 1936

Congleton Open Air Swimming Bath

The Borough of Congleton have opened a new open-air swimming bath and a children’s paddling pool adjoining the bath. The dimensions of the bath are 105ft. by 45ft., with a depth of 3ft. at the shallow end and deepening to 7ft., with an extended length of 20ft. at a depth of 9ft. to give facilities for high diving. The bath, the capacity of which is 180,000 gal. of water, is constructed in reinforced ferro-concrete, and finished in Snowcrete. The faience scum channel round the bath also serves the purpose of a bathers’ handrail. Longitudinal black markings are formed in the bottom of the bath for the guidance of swimmers when racing, and the various depths are indicated along the sides of the bath. A spacious surround has been provided, and to prevent contamination in the bath from surface drainage, the surface of this is connected by channels to the drainage system. The diving stage is in accordance with A.S.A requirements, consisting of a 5m. (16ft.) high diving stage, with springboard at 3m. (9 ft.) and facilities for diving from other heights.

Filtration Plant

This plant is comprised of two vertical air scoured filters, operating at a filtration speed of 219 gal. per sq.ft. area per hour, when dealing with 80,000 gal. of water per hour. A complete circulation of the contents of the swimming bath is once every six hours. The filters are cleansed by means of a reverse flow of filtered water, together with additional agitation of the filter beds, by means of compressed air, which is supplied by a “Bell” air compressor, driven by a Verity’s 6 h.p. slipring electrical motor. The pumping equipment comprises one horizontal split-casing centrifugal pump, driven by an 8 h.p. Verity’s slipring type continuously rated induction motor. The pump is capable of delivering 30,000 gal. of water per hour against a total head of 35 ft. Suction is from the deepend of the bath, the water being filtered with a special strainer box which retains all foreign matter in the water.

Sterilisation is by the chlorine process. The chlorine gas is automatically injected into the delivery mains and is controlled by a panel of controls and gauges, which function automatically to deliver minute quantities of the gas in the water.

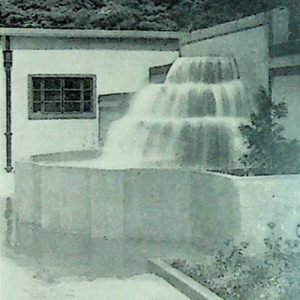

After filtration the water passes through a cascade aerator which is situated at the entrance end of the bath.

The clarity of water in the bath after full treatment is such that a 19 s.w.g. pin of platinum wire can be clearly seen at a depth of 6ft.

Dressing Accommodation

Large dressing rooms are provided for bathers, and access to these is controlled by attendants. The rooms are complete with shower baths and foot-sprays, while sanitary conveniences, washbasins, etc., are attached. Adequate dressing cubicles are installed, and the wire-basket and numbered rubber band system is in operation. The bathers’ entrance to the bath from the cubicles is intersected by a shallow trough of water through which it is compulsory to pass.

General

Sun-bathing terraces are provided, facing due south, and are screened from all winds. There is seating accommodation for over 200 spectators, and separate lavatory accommodation is provided. A refreshment kiosk is furnished for both bathers and spectators.

The whole of the structure and buildings is designed and erected in ferro- concrete. The front elevation consists of an entrance block, which includes storerooms, cashier’s office and entrance hall, with automatic turnstiles and large French windows opening on to the bathers’ and spectators’ terrace. On the opposite side of the bath at the farend, is the filter house. The whole scheme was designed by the borough surveyor (Mr. J. Hood) in collaboration with Messrs. L. G. Mouchel and Partners, Ltd., civil engineers, London.

Contractors and Subcontractors

The contractors for the construction of the swimming bath, buildings, paddling pool, etc., were Messrs. Bolton and Hayes, Ltd., Dolton.

Among the sub-contractors were:

- Purification plant, Messrs. Bell Bros. (Manchester), Ltd., Denton, Manchester.

- Pre-cast concrete work, Messrs. Concrete Unit Co., Ltd., Trafford Park, Manchester, and Messrs. Lightwood Concrete Aggregates, Ltd., Longton. Stoke-on-Trent.

- Steel framed windows, Messrs. Crittall Manufacturing Co., Ltd., Stretford, Manchester.

- Diving stage equipment, Messrs. Hunt and Son, Liverpool.

- Wire baskets and numbered rubber bands Messrs. Heaths (Eccles), Ltd., Patricroft, Manchester.

We are indebted to the Town Clerk (Mr Edward A. Plant) for the foregoing description and illustrations.

![]()