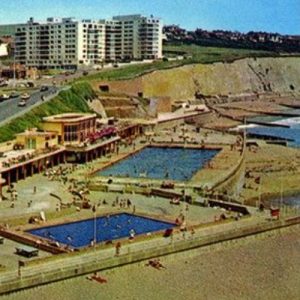

The Black Rock Lido opened in 1936. It was situated on Marina Drive to the east of the resort. It was around 3 miles west of Saltdean, where their lido would be built in 1937-38. The new Sea Lanes pool is three quarters of a mile further to the west.

The pool was lined with blue tiles, and the floor was sloped for two thirds of its length for safety. It took water from the sea where it was then filtered and sterilized with ozone for 8 minutes, to kill bacteria.

The facility had a waitress-service cafeteria and a bathers buffet. Areas to the east and west of the pool were set out as shingle sunbathing areas. The patrons could also access the natural beach from steps at either end.

1952 saw the pool opening on 20th April, much earlier than usual due to the heatwave.

It is generally thought that the pool was demolished to accommodate the new marina, but this is not true. The marina is adjacent to the east. Work started in 1971 but construction standards for controlling dust and noise were poor and visitor numbers fell. Eventually the pool started to subside although we don’t have any direct information linking this to the marina build.

The pool was closed in 1978 and demolished in 1979. It was left for many years as a slab surrounded by graffiti-covered hoardings. It’s position adjacent to the brand-new marina must have been an embarrassment. In 2013, the council went as far as asking the public for suggestions for potential uses for the site. Around that time, artists were using the area to create fabulous sand sculptures. After this, the site seems to have been a contractors compound with multiple shipping containers but by 2018 it was empty again. Some of the site has been reclaimed and landscaped alongside the obligatory Black Rock Car Park.

| Name | Black Rock Open Air Sea Water Bathing Pool Madeira Drive, Brighton, East Sussex, BN2 5UB, England |

| Coordinates | 50°48’49.5″N 0°06’28.6″W |

| Built / opened | 31st July 1936 by the mayor, Councillor Edward Denne, J.P. |

| Cost | £52,000 |

| Dimensions | 165′ x 60′ |

| Capacity | 334,000 gallons |

| Water type | Ozone-sterilized sea water |

| Depth(s) | From 2ft. 6in. at the shallow end, to 6ft. 6in at the deep end, with diving pit 20ft. by 15ft. by 8ft. 6in. deep. |

| Diving | Fixed platforms 3m and 5m |

| Changing facilities | 140 cubicles with showers, 1,200 Hyg-Gard-All hangers |

| Second pool | Rectangular paddling pool |

| Spectator seating | First floor terraces overlooking the pool to the south. |

| Designer | Mr. David Edwards, M.Inst.C.E., F.S I., Burough Engineer |

| Date closed | 1978 |

| Status | Demolished |

| On site now | Waste ground |

| Links | MISS BRIGHTON BEAUTY CONTEST – British Pathé |

| Last updated | 9th December 2025 |

Baths and Bath Engineering, September 1936

Black Rock Open Air Sea Water Bathing Pool and Lido, Brighton

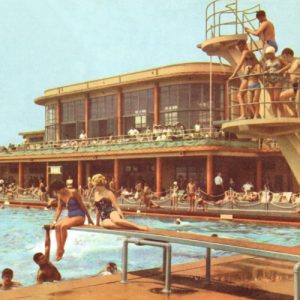

The new bathing pool and lido at Black Rock, Brighton, opened on July 31 last by the mayor Councillor Edward Denne, J.P. provides yet another addition to the numerous sea front amenities of this resort.

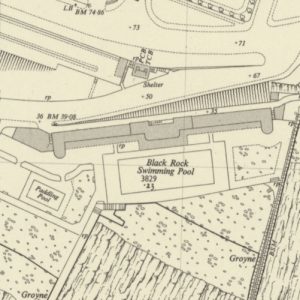

The site upon which the bathing pool is constructed is at the extreme east end of Madeira Drive. The available length was approximately 600ft. and the width 110ft. The bathing pool is placed nearly centrally on the site with the longitudinal axis east-west. The administration building lies immediately to the north of the pool and is set into the northern embankment in order to increase the area surrounding the pool. At the rear of this building is a new through way to the Undercliff Walk from Madeira Drive, the old access being over the bathing pool site. This through way consists of a reinforced concrete deck slab 10ft. wide, the embankment on the north being supported by a retaining wall 6ft. high, constructed in reinforced concrete and faced with cream “Cullamix” rendering (scraped finish).

To the west is the filter house, and pay office: the children’s paddling pool, and sunken gardens are to be constructed also at this end of the site.

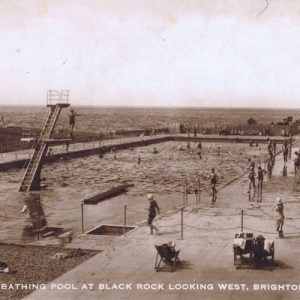

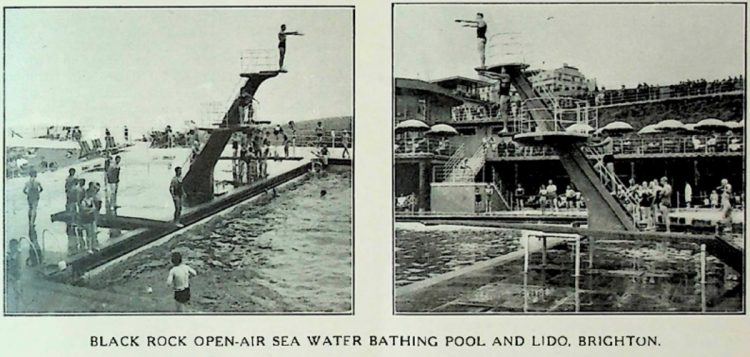

The swimming pool, constructed of reinforced concrete with a lining of “Cullamix” permanent blue tiling, supplied by the British Art Tiling Co., Ltd. of Mitcham, is 165 ft. long and 60 ft. wide. It has a capacity of 334,000 gal. and the depth varies from 2ft. 6in. at the shallow end, to 6ft. 6in at the deep end, with diving pit 20ft. by 15ft. by 8ft. 6in. deep. The floor of the bath has been sloped so that non swimmers are in perfect safety for about two thirds of the length. Eight sets of steps are provided, recessed into the walls of the bath.

The walls of the pool are designed as cantilever retaining walls reinforced on one side against water pressure and on the other against earth pressure. The toe of the wall is extended beyond normal proportions in order to reduce the bearing pressure to a maximum of ¾ ton per sq. ft., which, owing to the nature of the subsoil. was deemed the maximum safe working pressure.

The stresses used for the reinforced concrete work for the bath were 12,000 lb. per sq. in. tension in the steel and 750 lb. per sq. in. compression in the concrete; the concrete mixture being in the proportion of 3:1 ½: 1.

Transverse expansion joints are inserted at 30 ft. intervals, together with a central longitudinal joint. The wall joints consist of a copper strip connecting one bay to another and the space filled with bitumen and mastic. The floor joint consists of bituminised butt joint with each slab resting on a beam, the top of which is bituminised to allow movement.

Purified water is admitted to the pool through 18 inlets with phosphor bronze gratings, six in the shallow end and six in each of the side walls extending to within 30 ft. of the deep end. The gratings in each case direct the flow towards the deep end.

There are three main outlets at the deep end, constructed with large phosphor bronze gratings to preclude any danger of suction to bathers. In addition, approximately 15 per cent. of the flow passes over the scum channel at the deep end and returns to the filtration plant; on the other three sides the scum channel is 4 in. above water level and serves primarily as a handrail and as a channel to remove splashings The function of the scum channel at the deep end at water level is to produce surface movement and remove scum and dust.

The trend tiles to the steps are serrated to prevent slipping. The scum channel is of orange faience with phosphor bronze gratings, connecting on three sides to the drainage system and at the deep end to the suction main.

The reinforced concrete diving stage at the eastern end has two platforms, one at a height of 10ft. and a smaller one at 16ft. above the water level. It is faced in cream “Cullamix,” a smooth finish being produced by pressed fibre board shuttering. To obtain access to the bathing area from the administration building or the sun-bathing areas, bathers pass through sterilised water footbaths.

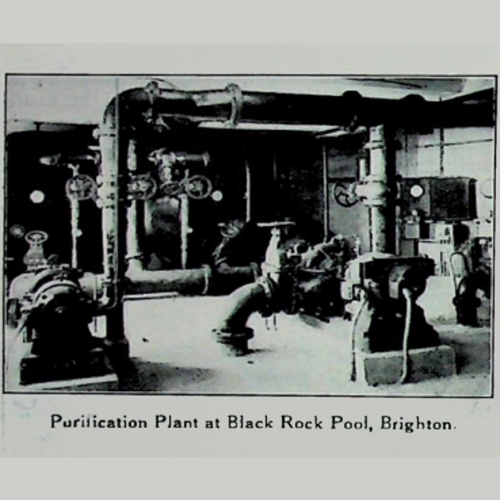

Pumping and Purification Plant

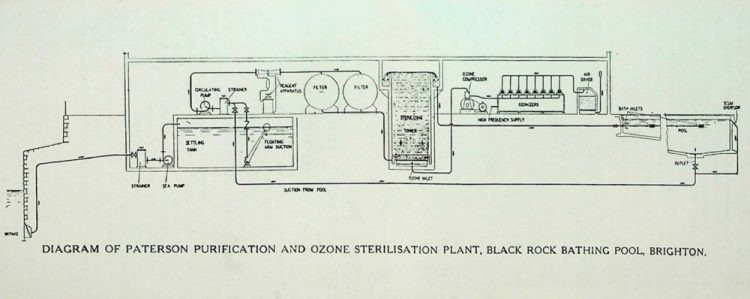

The filter house consists essentially of four units on two floors. namely, (1) filter house, (2) sterilisation tower and desiccators, (3) settlement tank, and (4) sea pump chamber. The whole structure below ground is in reinforced concrete, with floor level at 15.5 A.O.D., and consists of the settlement tank of 30,000 gal. capacity, the sea pump tank, and the lower portions of the sterilisation tower, which is 21ft. 6in. high, and extends to the roof of the building at 37.00 A.O.D., i.e., 10ft. above ground level. The ground floor contains the filters, circulating pumps, ozone plant, and desiccators, which are attached to the south wall of the sterilisation tower.

The sea-water suction main is 12 in. in diameter and runs from the filter house along the westerly groyne and drops down to an inlet with bell mouth and gratings at O.D., 370 ft. from the filter house. This main is also used as a discharge main when emptying the pool or washing the filters. The main enters the sea pump chamber at 19·00 A.O.D.; twin strainers are provided in this chamber, together with a “Freeflow” centrifugal pump of 45,000 gal. per hour capacity, direct coupled to a 15h.p. motor, and provided with an exhauster of 75 cu. ft. per min. displacement, driven by a 3 h.p. motor. The sea-water pump delivers to the settlement tank, the water after settlement being removed through a floating arm to piping connected with the suction main from the deep end of the pool to the circulating pumps.

The normal turnover period is 4 hours, and three circulating pumps have been provided, one of 90,000 gal. per hour capacity and two of 45,000 gal. per hour, so, if desired, a turnover period of 8 hours may be used. The pumps are low-lift centrifugal pumps, direct coupled to slip-ring electric motors, 400 volts, 3 phase, 50 cycles, and of 25 to 12 h.p. respectively.

Two horizontal filters 8 ft. diameter by 20 ft. long have been provided with high-speed air blower and 7 h.p. motor for washing the filters. They are designed for the normal 4-hour turnover period, approximately 90,000 gal. per hour of water being filtered. Wash water is discharged into the sea-water main.

The sterilisation of the filtered water is by the Paterson-Van der Made process. Ozone is generated in Van der Made electrodes fixed in cast metal cells each containing nine ozonisers, and in this instance, there are eight cells in the complete battery. The ozoniser consists of a special metallic tube carried in a suitable support within a glass cylinder, which is surrounded by water. A high voltage current discharges silently from the metallic tube, through the glass into the water, which is connected to earth.

The air to be ozonised is admitted at one end of the ozoniser and passes through the narrow space between the metallic tube and the glass cylinder. The continuous discharge of high-tension current across this space converts the oxygen in the air into ozone. The ordinary electric current, 400 volts, 50 cycles, is transformed to vary between 5,000 volts and 8,500 volts, as required. and the frequency is changed by a frequency changer to 500 cycles.

Assuming normal circulation is taking place and filters, and coagulating agents have removed the suspended and dissolved organic matter, then the ozone is free to act on the bacteria which have accrued. To perform thism the ozone is pumped to the base of the sterilisation tower and here has 8 min. association with the water, the period necessary to kill all bacteria. Vater and ozone rise to the overflow cill at the top of the tower and thence descend by the delivery main to the bath inlets.

The whole of the plant was supplied by the Paterson Engineering Co., Ltd., of London.

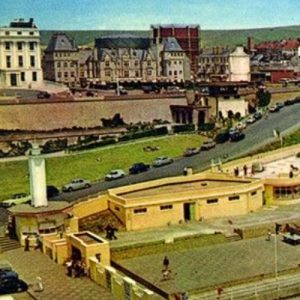

Administration Buildings

On the north side of the pool stand the administration buildings. The dressing cubicles are placed on the east and west of the central portion, which consists of large cafe, waitresses’ and service rooms at first floor level, and bathers’ buffet, kitchen, and manager’s and attendants’ offices at ground floor level. The cafe, with large sliding windows, offers a magnificent view of the coastline and the sea.

The dressing accommodation provided is 70 cubicles each for both sexes, with shower baths included. Fullest consideration las also been paid for hygienic storage of the bathers’ wearing apparel, by the provision of the clothes-hanger system known as ”Hyg-Gard-All” hangers, of which Mr. James Sieber, of Africa House, Kingsway, London, is the patentee The total number installed is 1,200, i.e., 600 for each sex. One of the numerous advantages of these ingeniously and solidly constructed hangers is that the bathers’ clothes are not shut up in a confined space, as the hangers with the clothes are stored in the open by suspending them on a framework. This permits a thorough airing of all garments and prevents the accumulation of odours, and any dampness from rain or perspiration is speedily removed. Quicker changing, and utmost reservation of all wearing apparel are other points worthy of consideration. Last, but not least, the fact that the clothes storage is in the entire charge of an attendant, and inaccessible to the public, greatly increases the bathers’ confidence, as in the unlikely event of pilfering, such losses are traceable.

The ends of the building are occupied by semicircular extensions for a shop and first aid station, with bathers’ and public lavatories at the back. A colonnade extends along the whole ground floor of the building 10ft. in width. Access to the roof from ground level is provided by steps, and the flat roof is used as a tea terrace and sun deck.

The colonnade and cafe are finished in orange faience, with a contrasting green motif on the beams and green capping to the columns. The remaining surfaces are treated with cream “Cullamix” rendering, scraped finish, and the paving of the colonnade is non-slip “Cullamix” tiles.

The administration buildings consist of a steel framed structure with brick filling and a pre-cast hollow beam concrete roof.

Sunbathing Areas

Portions of the site to the east and west of the pool are utilised as sunbathing areas and consist of graded shingle bench. In addition, the natural beach between the two groynes immediately in front of the pool is open to bathing pool patrons. access being obtained from the site by steps at the east and west ends of the pool.

Car Park

Immediately adjoining the west end of the site, at the main entrance, a car park is being constructed behind a new sea wall, the reclaimed land being raised by filling to road level.

Contractors and Subcontractors.

- General contractors for buildings, James Barnes and Sons, Brighton.

- General excavation and construction of retaining wall to throughway, H. Pannett, Ltd., Brighton.

- Pumping, filtration and purification plant, Paterson Engineering Co., Ltd., London.

- Steelwork, A. IE. Watson and Co., London.

- Concrete flooring, Seigwart Fireproof Floor Co., London.

- Paropa roofing, Frazzi, Ltd., London.

- Faience work, Carter and Co., Ltd., Poole, Dorset.

- Cullamix tiling to pool and colonnade, British Art Tile Co., Mitcham.

- Plastering, Over Bros., Brighton.

- Electrical installation, E. E. Fellingham, Brighton.

- Plumbing, W H Fellingham and Sons, Brighton.

- Pavement lights, Lenscrete, Ltd., London.

- Metal windows, Crittall Manufacturing Co., Ltd., Ashford, Kent.

- Cubicles, Venesta, Ltd., London.

- Terrazzo work, Diespeker and Co., Ltd., London.

- Hyg-Gard-All clothes hangers, James Sieber, London.

General.

The whole of the scheme, estimated to cost £52,000, has been carried out under the direction and supervision of the borough engineer, Mr. David Edwards, M.Inst.C.E., F.S I. The general manager of the pool is Mr. John Jenkyn.

![]()