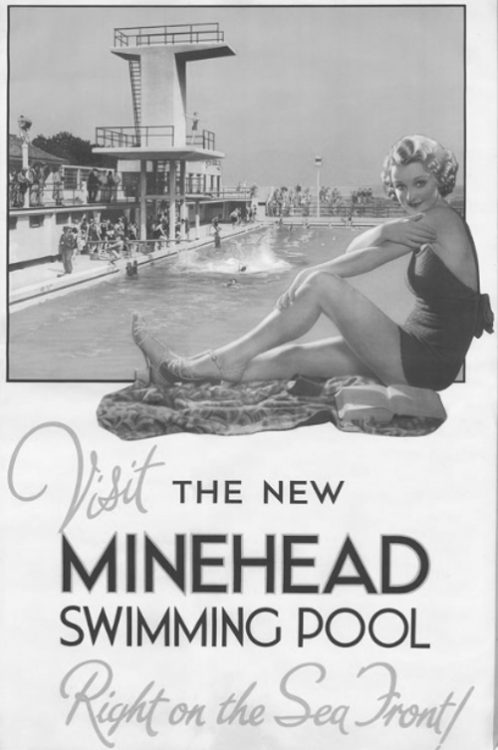

Mr Geoffrey Luttrell proposed the idea of an outdoor pool to the Council at Minehead after they offered businesses the chance to acquire land on the Eastern seafront. After some wrangling, the plan was approved and Minehead became the site of a privately owned pool of international, Olympic competitive standards.

The pool opened in 1936. The pool saw many international swimming competitions as well as hosting a popular swimming club and water polo team. The sea water was filtered, chlorinated, and heated. It took eight tides to fill the pool from empty which was done via a pipeline leading into the pool.

The site had some covered seating for spectators and there were swimming and diving entertainments as well as, apparently, log rolling events.

The site was used as a mustard gas de-contamination centre during WWII.

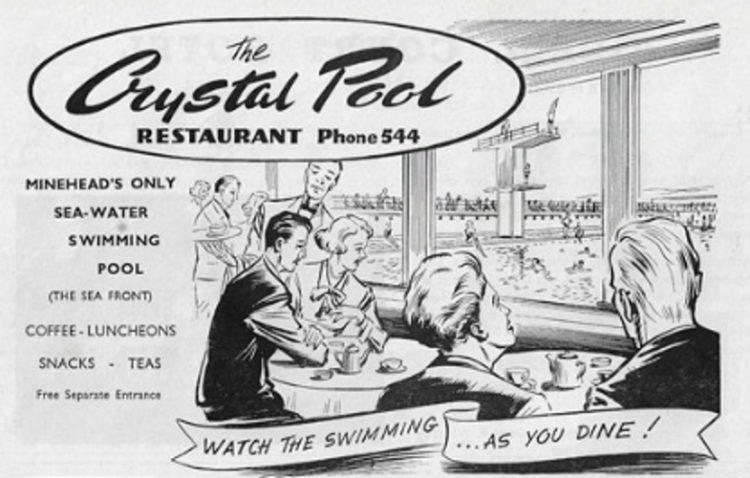

After the war Luttrell decided to sell and the Council had the opportunity to purchase the site for the town, but they passed so it went to a group of businessmen who set about making improvements. The spectator stand was converted into the Crystal Pool Restaurant, and a further building was added at the front as an amusement arcade.

The owners ran the pool for a number of successful years but eventually it began losing money and it was purchased by Butlins during the 1960’s to supplement their Minehead camp next door although that already had its own outdoor pool. Butlins operated the pool for some 20 years but eventually it was closed and left to deteriorate for another 10 years. It was finally demolished in 1991.

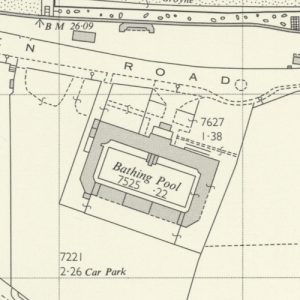

| Name | Minehead Bathing Pool Trinity Way, Minehead, Somerset, TA24 6GJ, England |

| Coordinates | 51°12’22.9″N 3°27’54.3″W |

| Built / opened | 13th June 1936 by Sir Robert Horne, Chairman of the Great Western Rail Company |

| Cost | £20,000 |

| Dimensions | 165′ x 60′ |

| Capacity | 400,000 gallons |

| Water type | Filtered and chlorinated sea water |

| Depth(s) | 3′ at each end, sloping to 4′ 6″, then 6′ 6″ to 15′ central diving pit |

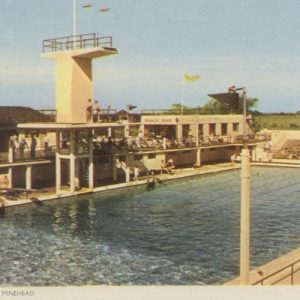

| Diving | 1m and 3m springboards, 3, 5m and 10m fixed boards |

| Changing facilities | 100 cubicles, 400 baskets |

| Second pool | N/A |

| Spectator seating | Seating for 350 spectators |

| Designer | Mr. Edwin Gunn, A.R.I.B.A., architect |

| Date closed | Circa 1985 |

| Status | Demolished 1991 |

| On site now | Housing |

| Links | AQUATIC CHAMPIONS AT MINEHEAD – British Pathé |

| Last updated | 16th September 2025 |

Baths and Bath Engineering, August 1936

Minehead Open Air Swimming Pool

The new open-air swimming pool at Minehead, built for Mr. G. I. Luttrell, of Dunster Castle, which was opened by Sir Robert Horne on June 13, is situated on the sea front and the approach is laid out in lawns and flower beds.

The pool is built to A.S.A standard, being 165 ft. by 60 ft., with depth varying from 3 ft. at each end to 15ft. under the diving stages which are up to 10m, with springboards (Pete Desjardins’ patent) at 1 m. and 3 m.

The bottom and sides of the pool are of reinforced concrete; the sides being lined with polished pre-cast slabs which were used instead of forms for the concrete construction. They are surmounted with pre-cast blocks containing a scum channel and forming a marginal seat 15 in. wide and 12 in. above the surround. This enables surface dirt to overflow into the same drains which take away water from the surround, which is at the same level as the scum channel. The bottom of the pool is faced with polished Snowcrete, with black lines 6 ft. apart for racing lanes.

Purification Plant

The water is maintained at the required standard of purity by a modern filtration plant employing the chlorine-ammonia system. Water is drawn off from two large sumps at the deepest part of the pool, and returned through four inlets, two at each end. Two pumps are installed, which may be used together or independently, the larger, of 12 h p., being capable of pumping 50,000 gal. of water an hour, and the smaller 12,500 gal. per hour. The large pump can give an eight-hour turnover and the two together can pass the whole content of the pool (400,000 gal. of water) in less than 6 hours. The same pumps are used for recharging from the sea into a settling tank of 50,000 gal. capacity, and from there, after settling, into the pool. It is possible to draw from the sea with one pump, while the other is continuing with the normal circulation.

Before returning to the pool, the water passes through two horizontal pressure filters, each with two compartments, first receiving a regulated dose of sulphate of alumina. This is drawn into a venturi tube, from a positive shunt feed tank, fitted with regulator valve and meter. Any excess of alumina can be neutralised by a second shunt feed using soda, or some other alkali.

After filtration, the water passes a throat through which is drawn ammonia gas, injected dry, by a calibrated instrument with meters and back pressure valve. From there it enters the aerator, a large vertical tank with baffle plates, which receives air from a venturi tube. Chlorine is injected in solution after aeration, to avoid loss during this process.

General

The system of racks and numbered wristlets is employed for the dressing accommodation. The 100 cubicles may be used by six bathers each in the course of a session; 400 clothes baskets are provided, and 250 more are to be added. Bathers pass through foot baths with overhead showers which are chromium plated, as are all other metal fittings.

Spectators have a separate entrance, which leads on to the terrace above the dressing accommodation. The terrace is protected from the sea breeze by a glazed screen running the whole length of the building. At one end is the restaurant, glazed all round, built so that in hot weather, one end can be opened by sliding the folding doors back to the wall. One side contains seven double doors which also fold against each other.

At both ends of the pool, for seating 350 spectators, are stands, which have steps down to the sun-bathing enclosure, which runs the length of one side of the pool, and where bathers and non- bathers may mix, but from which to the pool access is only by way of a foot-bath. The design thus ensures that the pool surround will be kept clear of non-bathers.

A buffet for bathers has been provided downstairs, with a second small bar to the dressing room. Power is supplied by 3 and 12 h.p. gas engines with an output of 18 kw., so that they can also provide lighting for the pool, etc. The floodlighting is by gas, with 12 standards carrying 3-4,000 candle-power lamps.

Engineers and Contractors.

The following were responsible for the construction of the scheme:

- Architect, Mr. Edwin Gunn, A.R.I.B.A.

- Quantity surveyor, Mr. W. T. Hills, F.S.I.

- Reinforced concrete designers, Indented Bar and Concrete Engineering Co., Ltd., of London.

- Pumping and filtration plant engineers, Messrs. Young, Austen and Young, London.

- Clerk of the works, Mr. Salisbury Brown.

- The general contractor was Mr. A. E. Farr, of London, the engineer-in-charge being Mr. R. Febrey.

Among the sub-contractors were:

- Cubicles, Flexo Plywood Industries, London, Messrs. J. Burgess, and Sons, Minehead.

- Clothing racks, gates, etc., Potter Rax Gate Co., Ltd. London:

- Diving equipment, etc., Messrs T. M. Gardner and Co., Hoddesdon, Herts.

- Railings, ladders, etc., Messrs. Hider and Son, Parkfield-road, Torquay.

- Metal windows and screens, etc., Messrs. Hopes, Ltd., Smethwick, Birmingham.

The superintendent of the pool is Mr. J Newton.

![]()