Banbury Lido was built with the assistance of a £4,000 grant from the National Fitness Council and cost £7,900 for the build plus £1,263 for the purification plant. It was opened on 23rd May 1939 by Alderman J. C. Fuller, J.P., C.C., a member of the Grants Committee.

The site was 1.5 acres and had a spacious car park, 108 cubicles and 432 lockers.

The pool was 165’ x 60’ and varied in depth from 2’ 6” to 10’ at the diving pit. The central column and bowls of the cascade at the shallow end of the pool, were in reconstructed stone, and the outer basin is rendered in green ‘Colorcrete.’

The National Cash Register Co., Ltd. Of London supplied a special cash recording and ticket issuing machine designed specifically for swimming pools. It recorded a variety of possible purchases or hires including costumes and caps. The ticket could also promote upcoming events on the reverse. This enabled the pool staff to know exactly how many people had attended between given times and made cashing up and recording at the end of the day much easier.

The pool had record attendance figures for its 60th birthday weekend in 1999 but by 2002, various problems including mounting maintenance issues caused its closure.

In 2005 a campaign to save the pool was led by the Open-Air Pool Support Group. 10,000 signatures were added to a petition to save the pool. 300 people demonstrated against closure outside a council meeting that postponed the axe and forced a new debate.

The campaign was successful, and Cherwell District Council and Banbury Town Council funded a refurbishment costing £1.5 million. The pool re-opened in 2009.

The pool has remained open since. In 2022, the pool had a solar heating system installed. In 2025 the facility re-opened for summer on 19th May following £130,000 of investment to provide new showers, toilets and improved changing facilities.

| Name | Banbury Lido aka Woodgreen Swimming Pool Woodgreen Avenue, Banbury, Oxfordshire, OX16 0HS, England |

| Coordinates | 52°03’41.1″N 1°21’01.3″W |

| Built / opened | 23rd May 1939 |

| Cost | £9,163 |

| Dimensions | 165′ x 60′ |

| Capacity | 356,000 gallons |

| Water type | Fresh water |

| Depth(s) | 2′ 9′ to 10′ |

| Diving | 5m fixed board, 3m firm board, 3m springboard, 1m firm board, 1m springboard |

| Changing facilities | 108 cubicles, 432 lockers |

| Second pool | N/A |

| Spectator seating | |

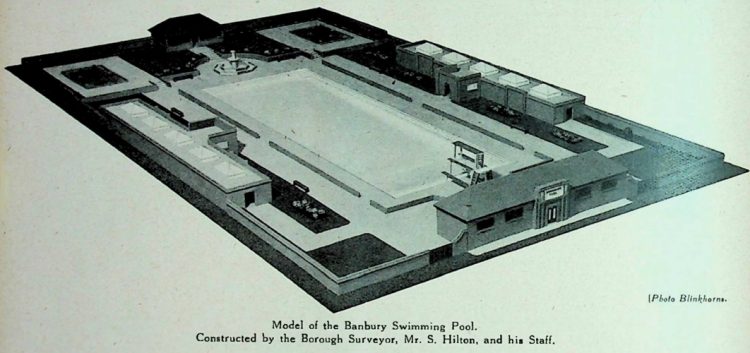

| Designer | Mr. Sidney Hilton, M.Inst.M. and Cy.E.. M.R.S.I., borough engineer and surveyor |

| Date closed | N/A |

| Status | Open |

| On site now | The pool |

| Links | Woodgreen Leisure Centre – 50m Swimming Pool |

| Last updated | 24th September 2025 |

Baths and Bath Engineering August 1939

Banbury’s New Swimming Pool

The modern open-air swimming pool at Banbury, which has, been constructed from the design of Mr. Sidney Hilton, M.Inst.M. and Cy.E.. M.R.S.I., the borough engineer and surveyor, occupies a site of approximately one and a half acres. Ald. J. C. Fuller, J.P., C.C., a member of the Grants Committee of the National Fitness Council, which granted £4,000 towards the cost of the pool, performed the official opening of it in May last.

At the rear of a spacious free car park, access to the enclosure is gained by passing through the main entrance block. This building accommodates the purification plant, spectators’ conveniences, stores, superintendent’s office, and a central vestibule equipped with registering turnstile and ticket office. The rear exit from the vestibule emerges upon a raised circular terrace. At either end of the terrace, steps descend to a spectators’ promenade, and the pool surround which is reserved for bathers, and also to the dressing rooms. The women’s dressing room is on the north side, and the men’s on the south side.

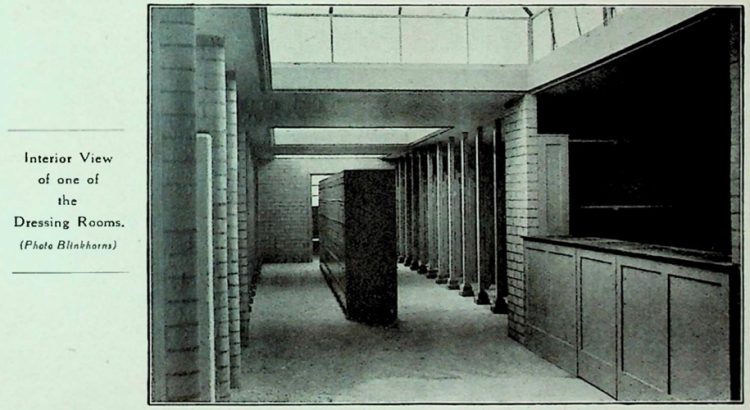

Dressing Accommodation.

In the dressing rooms cubicles, 54 for each sex, are provided on either side of the building with lockers, 216 for women and 216 for men, arranged in the centre. An attendant’s enclosure, showers and foot sprays, and conveniences, and a large changing room for parties are also furnished. All bathers before entering the pool, and also on returning, pass through a central corridor at the end of which is placed a compulsory footbath.

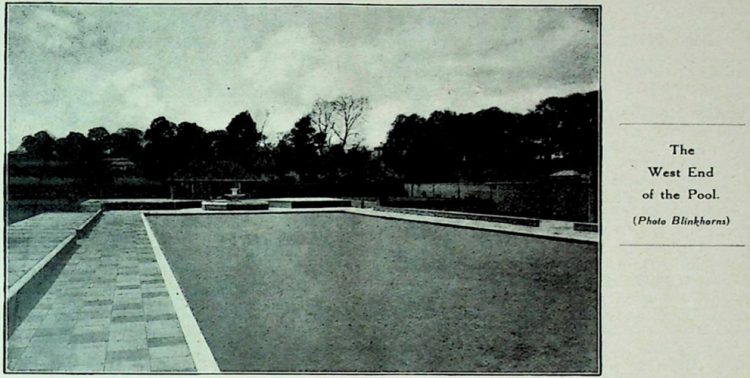

The Swimming Pool and its Surrounds.

This is placed centrally in the enclosure. The walls are of mass concrete construction; all joints being treated with ‘Maclast’ bituminous jointing material. The floor is of reinforced slab construction; natural cork being used in all joints. The scum channel is in adamant reconstructed stone. The pool is 165 ft. long by 60 ft. wide, the depth of water varying from 2 ft. 9 in. to 10 ft. at diving pit. The capacity is 356,000 gal. of water.

The diving stage provides a 5m. fixed board, 3m. firm board, a 3m. springboard and also a 1m. firm board. A 1m. springboard is also provided separately. The surround of the pool is paved with non-slip flags in buff and red, the colours being laid random. A dwarf wall having a coping of buff quarry tiles separates this surround from an outer promenade of concrete paving. Between the promenade and the buildings, turf and flower beds are introduced. A border of trees and shrubs is planted around all boundary walls. The central column and bowls of the cascade at the shallow end of the pool, are in reconstructed stone, and the outer basin is rendered in green ‘Colorcrete.’ At the rear of the cascade, circular steps give access to a raised cafe terrace and the cafe. The terrace wall is bordered by rose beds. The centre portion is paved with crazy York stone paving on either side of which is a turfed area extending to a border of trees and shrubs.

Purification Plant.

The ‘ Unifilters ” purification plant circulates the entire contents of the pool once every six hours. The components include a quick opening strainer box, with ample grid area, placed before a centrifugal pumping unit driven by an electric motor. On the discharge of the pump is fitted a venturi tube which operates the shunt feed chemical gear and also a mercurial flow gauge, giving an indication of the hourly capacity of the plant.

The filtration plant consists of two horizontal filters of the ‘Unifilters’ divided bed type. The manufacturers point out that the advantage of this type of filter, of outstanding importance, is the reduction in the amount of wash water required for cleansing. The air necessary for the cleansing is obtained by means of a special self-injector, requiring no motive power. No compressor is therefore necessary and this alone, they add, reduces the working cost to the very minimum consistent with high efficiency. Chloramine treatment follows filtration, and the purified water is then returned to the cascade. The aerated water enters the pool at the shallow end by means of three ‘Unifilters’ spreaders, which are equivalent to nine separate inlets. The water is evenly distributed throughout the whole width of the pool.

Miscellaneous Equipment and Material.

In addition to the registering turnstile already mentioned a non-registering type is installed. These rectangular top turnstiles and also a pair of gates were supplied by Sir W. H. Bailey and Co., Ltd., of Salford.

The cash recording and ticket issuing machine is the special baths model made by The National Cash Register Co., Ltd., London. On pressing the appropriate keys, the indicator displays the amount and the kind of transaction. At the same time this amount is added to the existing total registered inside the machine, and a ticket issued printed with full details of each transaction. This printed ticket gives the amount and class of transaction. In addition, the date of issue, consecutive number of the transaction, and the full title and address of the pool are given, whilst on the reverse notice of forthcoming events and other advertising matter can be displayed. Any number of keys up to 18 are available describing the kind of transaction. Those in use with the system at Banbury are :-(1) Men’s swim; (2) ladies’ swim; (3) children’s swim; (4) season ticket adult; (5) season ticket child; (6) costume; (7) towel; (8) cap; (9) spectator. Each transaction is automatically dissected and added to its particular total. Finally, the printed detail strip enclosed within the machine records consecutively the amount and class of each transaction. Thus, in one operation each transaction is recorded, added, dissected, and a receipt given for it. At any moment of the day the actual takings and the total number of each class of transaction can be checked. By adjusting the detail strip at periodical intervals, a check can be made on the volume of attendance between any given times.

‘A’ quality ‘Sundeala,’ a rigid waterproofed homogeneous panelling material, manufactured by The Patent Impermeable Millboard Co., Ltd., Sunbury-on-Thames, has been used for partitioning and doors to the cubicles. The over-all size of the lockers, supplied by Messrs. Brierley and Kershaw. Ltd., Rochdale, is 72 in. by 12 in. by 12 in. double tier type, fabricated throughout from 18G C.R.C.A. P.F. and finally sprayed with a special synthetic enamel. The legs have been sherardised prior to spraying. All locks are to differ and mastered.

The whole of the buildings is of brick construction. The entrance block and the cafe are roofed with dark red cross-cambered Marley tiles. The changing rooms have flat roofs and an ample provision of glazed lantern lights.

Contractors.

The general contractors for the pool, buildings and complete lay-out were Messrs. J. F. Booth and Son, Banbury, the contract price being £7,900. The contractors for the purification plant were Messrs. United Filters and Engineering, Ltd., London, the contract price being £1,263.

Among the sub-contractors, apart from those already mentioned, were:

- The Croft Granite, Brick and Concrete Co., Ltd., Croft, near Leicester – paving, all precast concrete and reconstructed stonework.

- T. M. Gardiner, Ltd., Hoddesdon, Herts – diving equipment.

- Macartney, Ltd., London – ‘Maclast’ bituminous jointing.

- N. W. Mitchell and Snow, Ltd., London – ‘Natcorex’ natural cork expansion joints.

- Wallace and Tiernan. Ltd., London – chloramine plant.

Mr. E. Bury, is the superintendent of the new pool.

![]()